|

|

|

|

|

Comparison of Characteristic Features of Inkjet Printers of Different Make and Model using Video Spectral Comparator

Piyush Thakur 1![]() , Navjot Kaur Kanwal 2

, Navjot Kaur Kanwal 2![]() , Shilpa

Nair 3

, Shilpa

Nair 3![]() , Parveen

Kumar Janjua 4

, Parveen

Kumar Janjua 4![]()

1 MSc-Forensic

Science, Department of Forensic Science, Dr. Harisingh

Gour Vishwavidyalaya (A Central University), Sagar, Madhya Pradesh, India

2 Associate

Professor, Department of Forensic Science, Guru Ghasidas

Vishwavidyalaya (A Central University), Bilaspur, C.G., India

3 PhD Scholar, Department of Forensic Science, Dr. Harisingh

Gour Vishwavidyalaya (A Central University), Sagar, Madhya Pradesh, India

4 Professor & Head, Department of Forensic Science, Kalinga

University, Raipur, C.G., India

|

|

ABSTRACT |

||

|

The present

study aims to identify and analyze the individualizing characteristics of

documents printed using various inkjet printers through non-destructive

examination with a Video Spectral Comparator (VSC-40). Printed samples were

collected from twelve different inkjet printer models, primarily from the

EPSON, HP, Canon, and Brother brands. Standardized A4 paper was used to

ensure uniformity in analysis. Under VSC-40 magnification, several

distinguishing features such as edge sharpness, dot roundedness, blooming

effect, extraneous dots (satellite drops and overspray), directional

artefacts, line defects, and banding patterns were systematically examined.

The study observed that EPSON printers, utilizing piezoelectric technology,

demonstrated superior edge sharpness and minimal blooming effects compared to

other brands. Printers like Brother-DCP J140w exhibited pronounced blooming

and banding defects. Features such as directional tailing and consistent line

defects proved useful for determining the type of printing technology

employed and for linking documents to their sources. The findings confirm

that VSC-40 imaging provides a reliable, non-destructive means for the

forensic differentiation of inkjet-printed documents, enhancing authenticity

verification and source identification processes in questioned document

examination. |

|||

|

Received 28 May 2025 Accepted 29 June 2025 Published 01 July 2025 Corresponding Author Navjot

Kaur Kanwal, kanwalnk@gmail.com DOI 10.29121/DigiSecForensics.v2.i2.2025.48 Funding: This research

received no specific grant from any funding agency in the public, commercial,

or not-for-profit sectors. Copyright: © 2025 The

Author(s). This work is licensed under a Creative Commons

Attribution 4.0 International License. With the

license CC-BY, authors retain the copyright, allowing anyone to download,

reuse, re-print, modify, distribute, and/or copy their contribution. The work

must be properly attributed to its author.

|

|||

|

Keywords: Inkjet Printers, Video Spectral Comparator (VSC-40),

Non-Destructive Examination, Forensic Document Analysis, Printer Identification,

Piezoelectric Printing Technology, Questioned Document Examination |

|||

1. INTRODUCTION

Document can be defined as “any material that contains written or printed information conveying some meaning or a message.” Document generally contains information about transactions such as agreements, wills ownership of properties, etc. It is quite often used as legal evidence of transaction, which makes it necessary to state its genuineness. Questioned documents are those whose authenticity and genuineness is unidentified. Document forensics deals with examination of questioned documents to provide information about its source, age, tools used to prepare the document, authenticity, authorship and many such individualizing features. With technological advancements, the creation of fraudulent documents is evolving. These days’ personal computers, scanners and printers are enough to generate fraud documents like ID proofs, passports, and agreements. Multiple tools and instruments are used to produce a single document that mimics the qualities of an authentic document. Such a forged document will contain composite features of all the processes involved in its creation. Thus when it comes to printed questioned documents, an examiner usually starts with identifying the printer or source from which the document has been created.

Printing is a process for mass reproducing documents containing text and images, using a master form template. Printing technologies have varied tremendously throughout the ages, although the two most commonly used printing methods are offset and digital printing Manualslib (2025). Offset printing also known as lithographic printing, uses a printing plate containing the master pattern image that is inked and transferred to a rubber blanket, then to a printing surface. This is coupled with an ink accepting printing area and an ink repellant non printing area to produce a perfect copy. The process is named offset because the print is transferred from the plate to the blanket, rather than it directly being impressed directly on to the paper. Offset technology can support high volume printing jobs and create multiple copies at a time. On the other hand, digital printing, a modern printing technology, reproduces digital images on to a physical surface. A digital file like PDF can be directly sent to the printer and a copy can be produced without the printing plate required in a lithographic process. It is a cost effective process that produces high quality prints Kipphan (2001). The most popular digital printing method includes inkjet printing and laser printing methods. This study shall focus on inkjet printing processes and the visualization of its characteristics under Video Spectral Comparator (VSC).

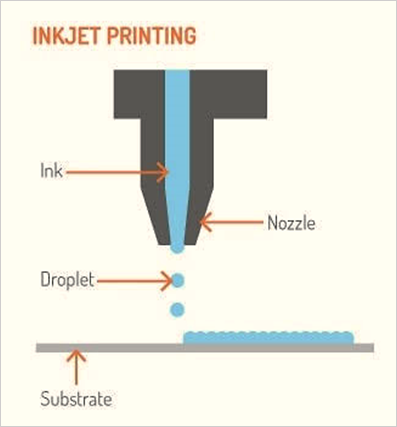

Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto a printing surface (Printing processes). They originated in the 20th century and went through various developments, and digital images that can be generated by computers were developed by companies like Hewlett- Packard (HP), Epson, and Canon. These printers are very popular and range from small inexpensive consumer models to expensive professional ones. Figure 1 explains the general working of an inkjet printer’s working.

An inkjet printer works by spraying extremely small spots of ink on to the paper to create a particular image. The inkjet mechanism consists of three principal components: The print head, the carriage or paper advance mechanism and the ink reservoir system. There are two main technologies used: 1. Continuous inkjet and 2. Drop-on-demand inkjet Wijshoff (2010). Continuous inkjet method employs a high pressure pump setup that directs the liquid ink from a reservoir through a nozzle to create a continuous stream of ink droplets. Whereas, drop-on-demand (DoD) printing prints in a way similar to dot matrix printer machines. A print head sweeps back and forth across the page making a pattern of dots. Two types of drop-on-demand printers are thermal DoD and piezoelectric DoD. As the name suggests, thermal DoD uses heat to excite and expand the ink bubble to force it out of the nozzle Lim et al. (2005) whereas piezoelectric DoD uses mechanical deformation of a piezoelectric tile in the nozzle to spray ink out. Most inkjet printers use the latter type of printing technology.

Figure 1

|

Figure 1 Inkjet Printing Technology |

During the investigation of any evidences, there are techniques that are destructive and non-destructive. A non-destructive technique is always a priority as the evidence is not destroyed in the process. Similarly, when it comes to document examination, there are physical non-destructive tests like microscopy, optical examination and chemical destructive techniques like toner analysis, elemental profiling etc. Investigation of printed documents can be done by comparing various features like spur marks [9], or intrinsic features like satellite drops, tails, dot placements etc., that are distinctive for a particular printer Li et al. (2004). Other methods in literature include extraction of edge sharpness, surface roughness and contrast features and applying a neural network to distinguish printing techniques. Passive techniques are useful for a non-destructive approach via microscopic and optical visualizing methods to detect minute flaws to differentiate two documents. Features like line width, raggedness, blooming effect, ink deficiency can be studied well using passive methods Mace (2010).

2. MATERIALS AND METHODOLOGY

Sampling: The sample documents were collected from different areas of Sagar district of Madhya Pradesh. A random sampling approach was undertaken and most printers of EPSON brand were encountered. The document contained all letters of the alphabet including the special symbols.

Sample production: White A4 papers of GSM 75, from the company ‘JK Copier’, manufactured in the year 2015, were used throughout the study to maintain uniformity. The sample documents were collected in the form of printed documents from 12 randomly selected inkjet printers. The list of selected printers is as displayed in Table 1

Table 1

|

Table 1 Different Make and Models of Inkjet Printers Selected for the Study |

||

|

Sr. no. |

Inkjet printer models |

Time since first use |

|

1 year |

||

|

2 |

EPSON L 120 |

2 years |

|

3 |

EPSON L 130 |

1 year |

|

4 |

EPSON L 210 |

3 years |

|

5 |

EPSON L 220 |

2 years |

|

6 |

EPSON L 355 |

2 years |

|

7 |

EPSON L 360 |

3 years |

|

8 |

EPSON L 800 |

1 year |

|

9 |

HP Desk jet K209a |

3 years |

|

10 |

HP Desk jet 3520 |

2 years |

|

11 |

Canon MP287 |

3 years |

|

12 |

Brother-DCP J140w |

3 years |

Equipment used: VSC-40. The instrument is a high-quality imaging device by Foster+Freeman that allows an examiner to analyze various questioned documents under different lighting conditions and magnifications. It comes occupied with a desktop computer and an imaging system containing a CCD (charged coupled device) video camera and an illumination system with radiant energy sources, filters etc. Akao et al. (2002). The instrument was found to be adequate for the purpose of this research because of the availability of several magnification modes, digital documentation facilities and its non-destructive nature.

Methodology of Analysis: The sample document was placed inside the VSC-40’s imaging system, under the document platen. A CCD camera coupled with the desktop computer was used to visualize the image on the screen. Several magnification modes under the visible light were used to examine the intricate details of inkjet printing. The area of interest was captured, marked, and documented. The process was then repeated for all the samples while maintaining similar conditions for consistency.

3. RESULTS AND DISCUSSIONS

The following characteristics were noted during the examination of inkjet printed documents under VSC-40:

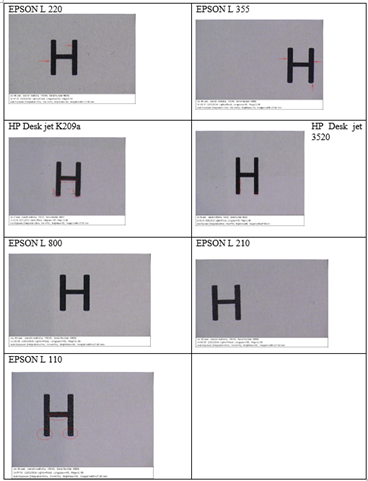

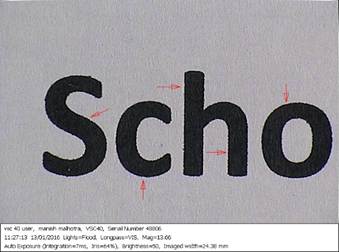

Edge sharpness: Edge can a be a good deciding factor when it comes to identifying the printing technology. Since the mechanism of inkjet printers involves spraying of ink droplets onto the substrate, there are minute level irregularities visible in the letter formation. High degrees of edge roughness were noted. Comparatively speaking, the printers of brand EPSON L 800 and EPSON L 355 showed higher edge sharpness than the others.

Figure 2

|

Figure 2 Edge Sharpness of Various inkjet Printer Models |

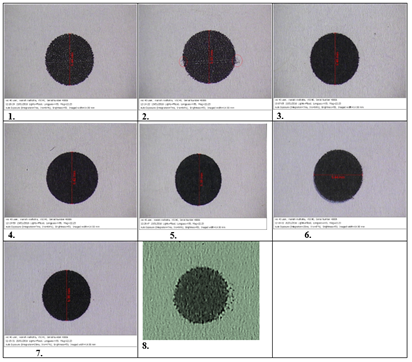

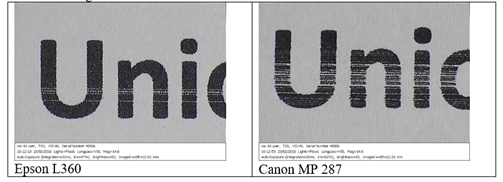

Dot roundedness: The clarity of any dot character is closely related to edge sharpness. Thus, the quality of paper affects the clarity of its edges. In the study, it was found that HP and EPSON printers showed a better dot clarity as compared to other printers as shown in Figure 3

Figure 3

|

Figure 3 Variations in Dot Roundedness as seen in Different Inkjet Printers Models, Namely, 1. EPSON L 110, 2. EPSON L 210, 3. EPSON L 220, 4. EPSON L 355, 5. EPSON L 800, 6. HP Desk jet K209a, 7. HP Desk jet 3520, 8. Canon MP287 |

Blooming effect: The absorption and subsequent diffusion of ink gives rise to blooming effect. Difference in the quality of paper fibers may show variances in its visualization as a cheap or recycled paper tend to have larger porosity resulting in a spider web like appearance. Larger irregularities may sometimes be visible to the unaided eye and appear as a poor-quality print. Other factors like humidity and temperature can also affect print quality. Among the selected brands, Brother-DCP J140W showed the most pronounced blooming effect as shown in Figure 4 and EPSON printers showed least to negligible blooming effect Figure 5 owing to its piezoelectric printing technology Li and Leung (n.d.).

Figure 4

|

Figure 4 Intense Blooming Effect seen in Brother-DCP J140W |

Figure 5

|

Figure 5 No Blooming Effect seen in Epson L 355 |

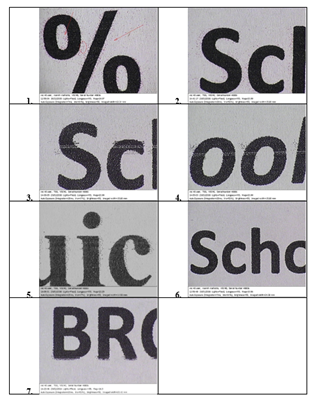

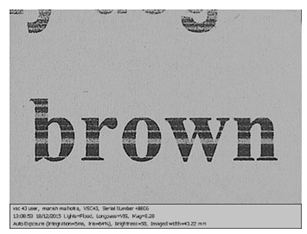

Extraneous dots: Satellite formation and line overspray are features indicative of print quality. Although these features come under the category of extraneous deposits, they have slight differences along with similarities. The similarity arises from the chronology of their formation being a secondary entity to form as a result of a primary phenomenon. For instance, the satellite marks are the ink drops that gets separated from the parent ink drop during the printing process. On the other hand, image overspray arises from the ink drops that fall out of the text area i.e., the non-character region. Image overspray is an indication of a defective machinery and is typically found adjacent along the line in a consistent fashion. Printers like Canon MP287 and EPSON L 130 showed notable image overspray compared to the other samples. EPSON printers showed no drop satellite formation whereas the Canon printer produced larger drop satellites than HP printers. None of the EPSON printers except EPSON L 210 showed any such formation Sharma and Sharma (2021).

Figure 6

|

Figure 6 A Display

of Various Extraneous Dots: 1)

Satellite drops;

2)

Satellite drop

seen in HP Deskjet K209a; 3)

Image Overspray in Epson L 210; 4)

Image Overspray in Epson L 130; 5)

Image Overspray in Canon MP 287; 6)

Extraneous deposits absent in Epson

printers in Epson L110; 7)

Slight defects in Epson L 210 |

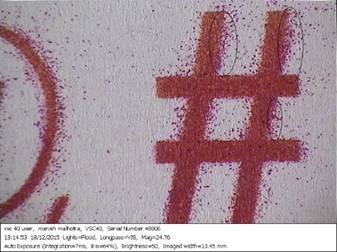

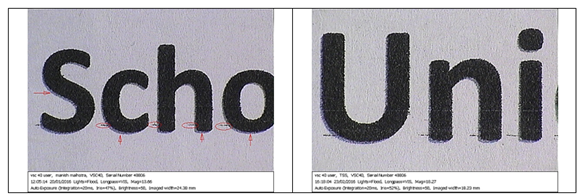

Directional artefacts: A printer can be unidirectional or bidirectional. Unidirectional printers print in a single direction and upon completing a line, returns to the start point for printing the next line. Bidirectional on the other hand prints alternatively by starting from the same direction where the previous line ended. On proper magnification the directionality of a printer can be ascertained by the ink spatter and tailing effect formed by the print machinery. HP Desk jet K209a showed tailing effect to the left side of the text, meaning unidirectional printing whereas EPSON L 355 showed tailing on both sides indicating bidirectional printing.

Figure 7

|

Figure 7 Tailing Effect (towards left) and Inking Defect as Seen in HP Desk Jet K209a |

Figure 7

|

Figure 8 Bidirectional Tailing Seen in Epson L355 |

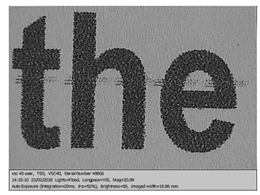

Line defects: These defects are exclusive to line printers that print line by line rather than fusing inking material directly on the text region. The two main components that can affect it is the print head and the print advance system. Variety in sizes, manufacturing, individual defects can have effects that can be used to differentiate between printers of same model. Especially when there is a permanent defect, the line defects will be consistent and continuous. The line defects found in this study have been shown in Figure

Figure 9

|

Figure 9 Line Defects Seen in Inkjet Printers |

Banding and Lining: A uniform band or line containing a void with insufficient ink supply is a banding or lining effect. It is more prominently observed in images that texts and visualized as dark and light alternative areas. This can efficiently be used to link two documents to detect its source. Figure 10 shows the prominent banding effect seen in Brother DCP J140w printer out of all the other samples considered for this study.

Figure 10

|

Figure 10 Banding Observed in Brother DCP J140w Printer |

4. CONCLUSIONS

This study attempted to demonstrate a nondestructive technique to record individualizing characteristics of inkjet printed documents using VSC-40 imaging device. To identify the printing technology as well as source specific characteristics, features like satellite drop formation, line defects, image overspray, edge sharpness etc. The experimental results showed promising individualizing features of inkjet printers under VSC examination. The following conclusions can be made from the results obtained in the study:

· Inkjet printers use a nozzle to spray ink to the desired substrate to produce copies of documents. The mechanism of spraying result in various irregularities which is comparatively lesser in other printers like laser.

· A pronounced ink overspray and blooming effect or satellite production are direct indicators of inkjet printing technology.

· Directional artefacts can be useful to establish the direction of printer and also differentiate whether two documents belong to the same source based on its directionality.

· Consistency in line and banding effects may refute or confirm an analysis.

· VSC can not only establish the printing technology but also differentiate between two documents based on the features discussed. Thus, it can be an excellent tool to carry out nondestructive analysis of printed matter.

CONFLICT OF INTERESTS

None.

ACKNOWLEDGMENTS

None.

REFERENCES

Akao, Y., Kobayashi, K., Sugawara, S., & Seki, Y. (2002). Discrimination

of Inkjet-Printed Counterfeits

by Spur Marks and Feature

Extraction by Spatial Frequency Analysis. Proceedings of SPIE, 4677.

Kipphan, H. (2001). Handbook

of Print Media: Technologies

and Production Methods. Springer.

Li, C., & Leung, S. (n.d.). The Identification of Color Photocopiers: A Case Study. American Society

of Questioned Document Examiners,

1(1), 8–11.

Li, C.-K., Chan, W.-C., So, C.-S.,

& Cheung, C. (2004). The Differentiation

of Color Laser Printers. Journal of the American

Society of Questioned Document Examiners,

7, 105–109.

Lim, J.-H., Kuk,

K., Shin, J.-S., Baek, S.-S., Kim, Y.-J., Shin,

J.-W., et al. (2005). Failure Mechanisms

in Thermal Inkjet Printhead Analyzed

by Experiments and Numerical

Simulation. Microelectronics Reliability,

45(3–4), 473–478.

Mace, J. C. (2010). Printer Identification Techniques and their Privacy Implications [Doctoral Dissertation, Newcastle University]. Newcastle University e-Prints.

Manualslib. (2025). Foster + Freeman VSC 80 user manual. Retrieved April 2025.

Prepressure. (n.d.). Printing processes. Retrieved April 2025.

Sharma, B., & Sharma, P.

(2021). A Study of

Certain Characteristic Features

of Various Printed

Documents to Determine the Type of Printer used in Forensic Investigations.

Turkish Journal of Computer and Mathematics Education

(TURCOMAT), 12, 1070–1076.

Wijshoff, H. (2010). The Dynamics of the Piezo Inkjet Printhead Operation. Physics Reports, 491(4–5), 77–177.

|

|

This work is licensed under a: Creative Commons Attribution 4.0 International License

This work is licensed under a: Creative Commons Attribution 4.0 International License

© DigiSecForensics 2025. All Rights Reserved.